How to Maintain a Powered Flex Conveyor — CamelConvey Maintenance Guide

Introduction to Powered Flex Conveyor

A Powered Flex Conveyor is a flexible and efficient material handling system, ideal for warehouses, distribution centers, and production lines. Its extendable and flexible design allows quick length adjustments, saving space while adapting to fast-paced operations. The CamelConvey Powered Flex Conveyor is engineered for durability, smooth telescoping performance, and easy maintenance, making it the perfect choice for modern logistics.

Why Preventive Maintenance Matters

Proper flex conveyor maintenance is not only about avoiding breakdowns but also about:

✔️Maximizing return on investment

✔️Reducing downtime

✔️Improving workplace safety

✔️Extending equipment lifespan

A well-structured preventive maintenance plan ensures your conveyor operates reliably while preventing costly unexpected shutdowns.

Powered Flex Conveyor Maintenance Schedule & Checklist

1. Daily Maintenance

● Cleaning: Remove dust, debris, and oil from rollers and gaps. Keep the motor and control box ventilation clear.

● Visual Check: Inspect cables for wear or damage.

● Belt Check: Ensure proper belt tracking and inspect for wear or tearing.

● Fastener Check: Tighten bolts and nuts, especially at track joints and mounting brackets.

● Operational Test: Verify start, stop, and emergency stop functions.

2. Weekly Maintenance

● Lubrication: Apply lithium-based grease to telescopic tracks, hinge shafts, and sliding parts.

● Electrical Inspection: Check for aging wires, loose terminals, or exposed conductors.

● Noise & Vibration: Listen for abnormal sounds from the motor or gearbox.

3. Monthly Maintenance

● Belt Tension: Ensure sagging does not exceed 2% of belt width; check joints for delamination.

● Structural Check: Inspect telescopic arms and steel supports for cracks, deformation, or rust. Clean tracks and apply anti-rust oil.

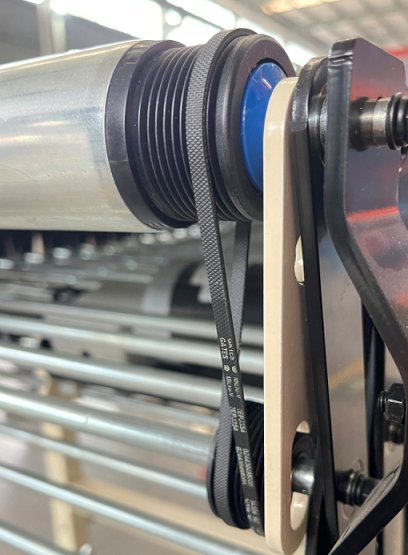

● Drive Components: Check pulleys, rollers, and alignment.

4. Quarterly Maintenance

● Clean dust and oil around the motor.

● Inspect motor wiring and connectors for overheating or looseness.

● Monitor motor temperature and running noise.

5. Annual Maintenance

● Inspect all bearings and rollers; replace worn components.

● Calibrate conveyor leveling and telescopic synchronization.

● Clean or replace relay and contactor contacts inside the control cabinet.

Additional Maintenance Tips

● Safety First: Always disconnect power before performing maintenance.

● Trained Personnel: Ensure only trained staff operate or service the conveyor.

● Maintenance Log: Keep a detailed log to track performance and detect early issues.

● Environment Check: Adjust cleaning and lubrication frequency for dusty, humid, or cleanroom environments.

Maintenance Frequency Overview

| Frequency | Key Tasks | |

| Daily | Cleaning, belt & cable inspection, fasteners, controls | |

| Weekly | Lubrication, electrical check, noise & vibration monitoring | |

| Monthly | Belt tension, structure, drive component inspection | |

| Quarterly | Motor cleaning, wiring check, noise monitoring | |

Annual | Bearing & roller replacement, calibration, electrical inspection | |

Conclusion

By following this structured maintenance plan, you can keep your CamelConvey Powered Flex Conveyor running safely, efficiently, and reliably. Regular preventive maintenance not only extends the conveyor's service life but also demonstrates your commitment to operational efficiency and workplace safety.

For professional training or customized maintenance solutions, reach out to CamelConvey today!